ABOUT US

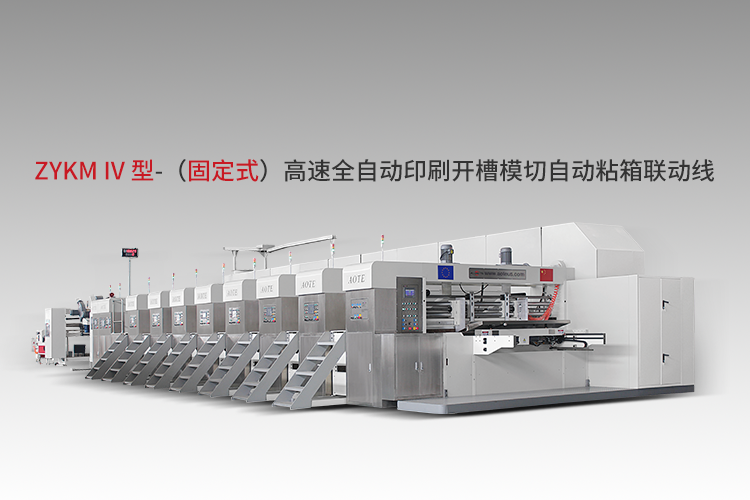

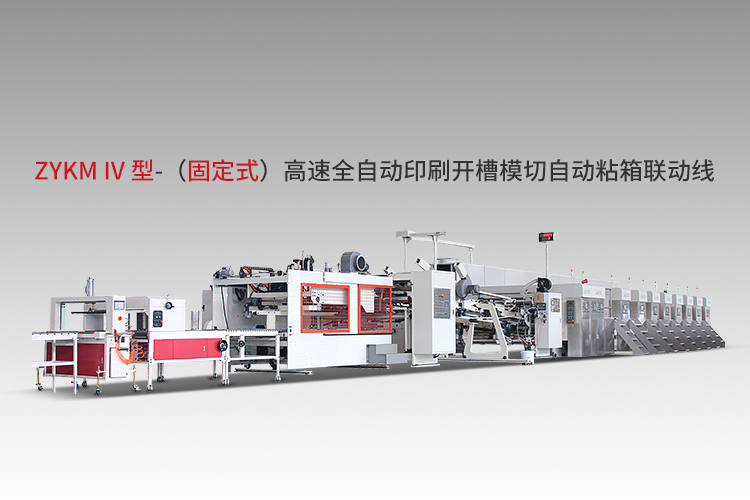

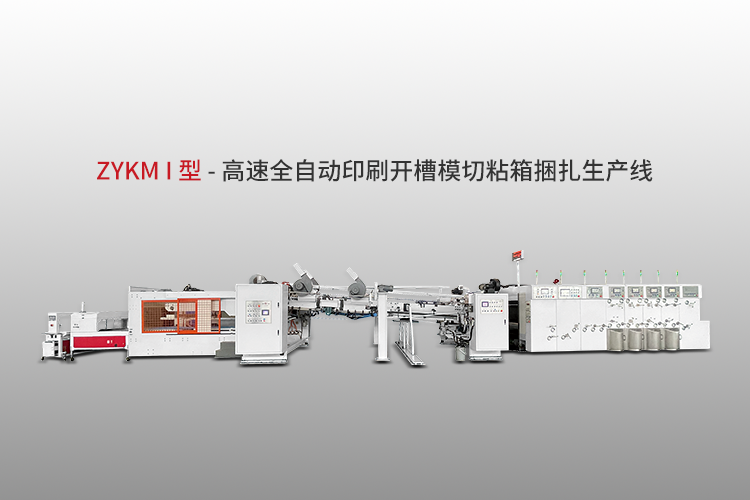

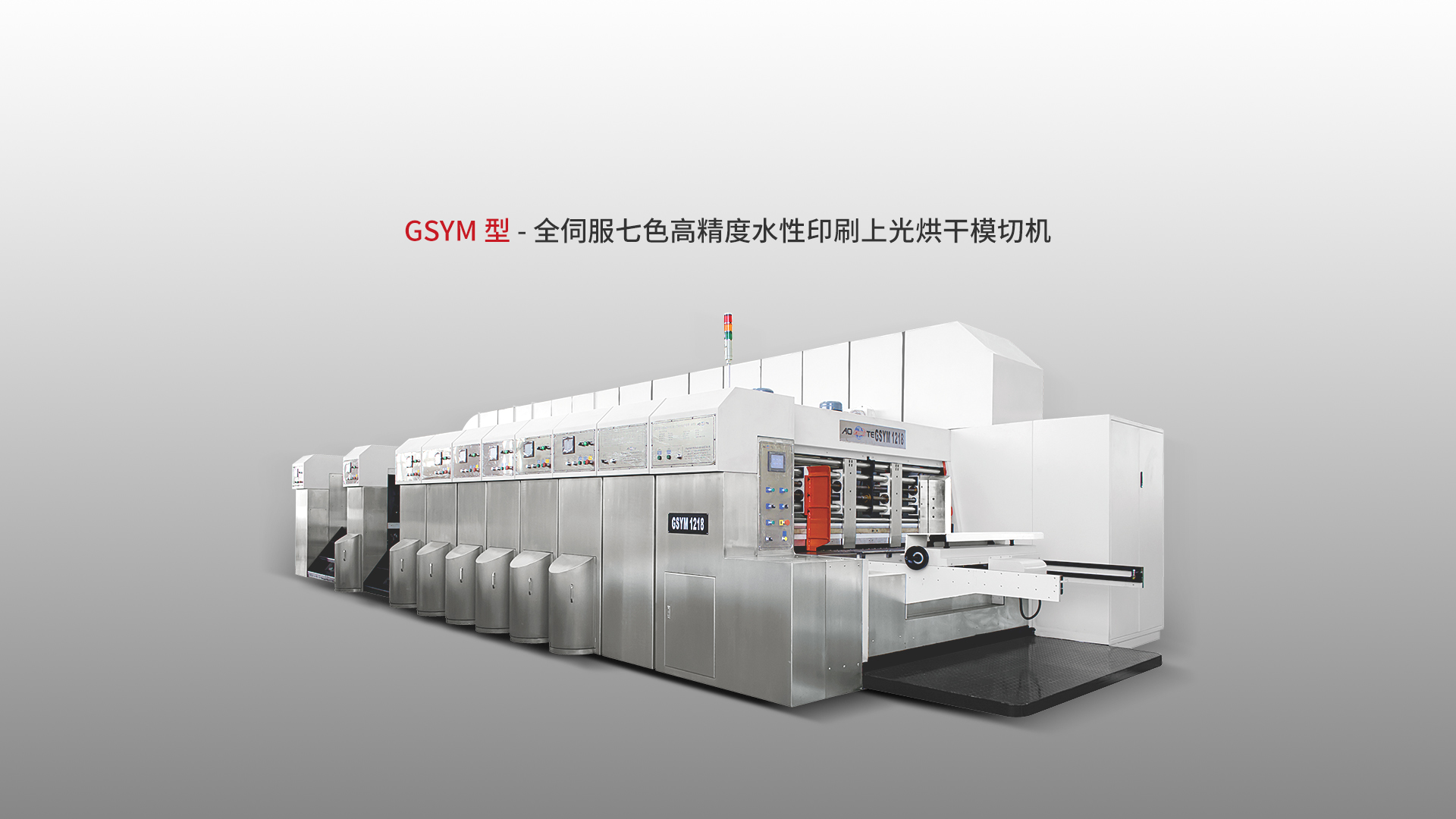

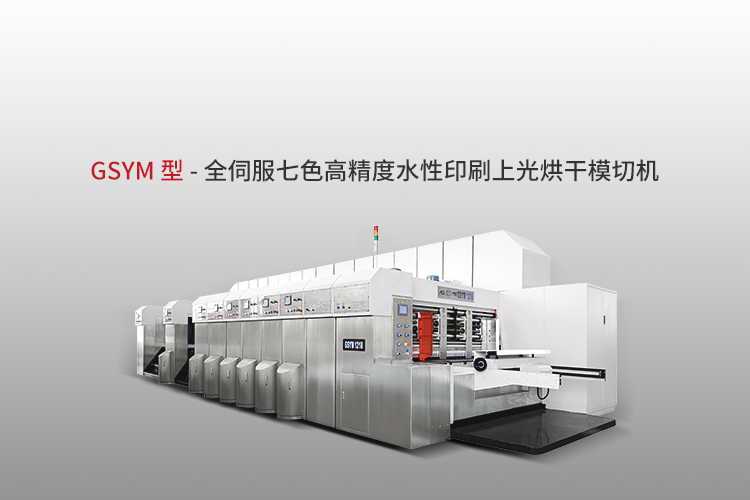

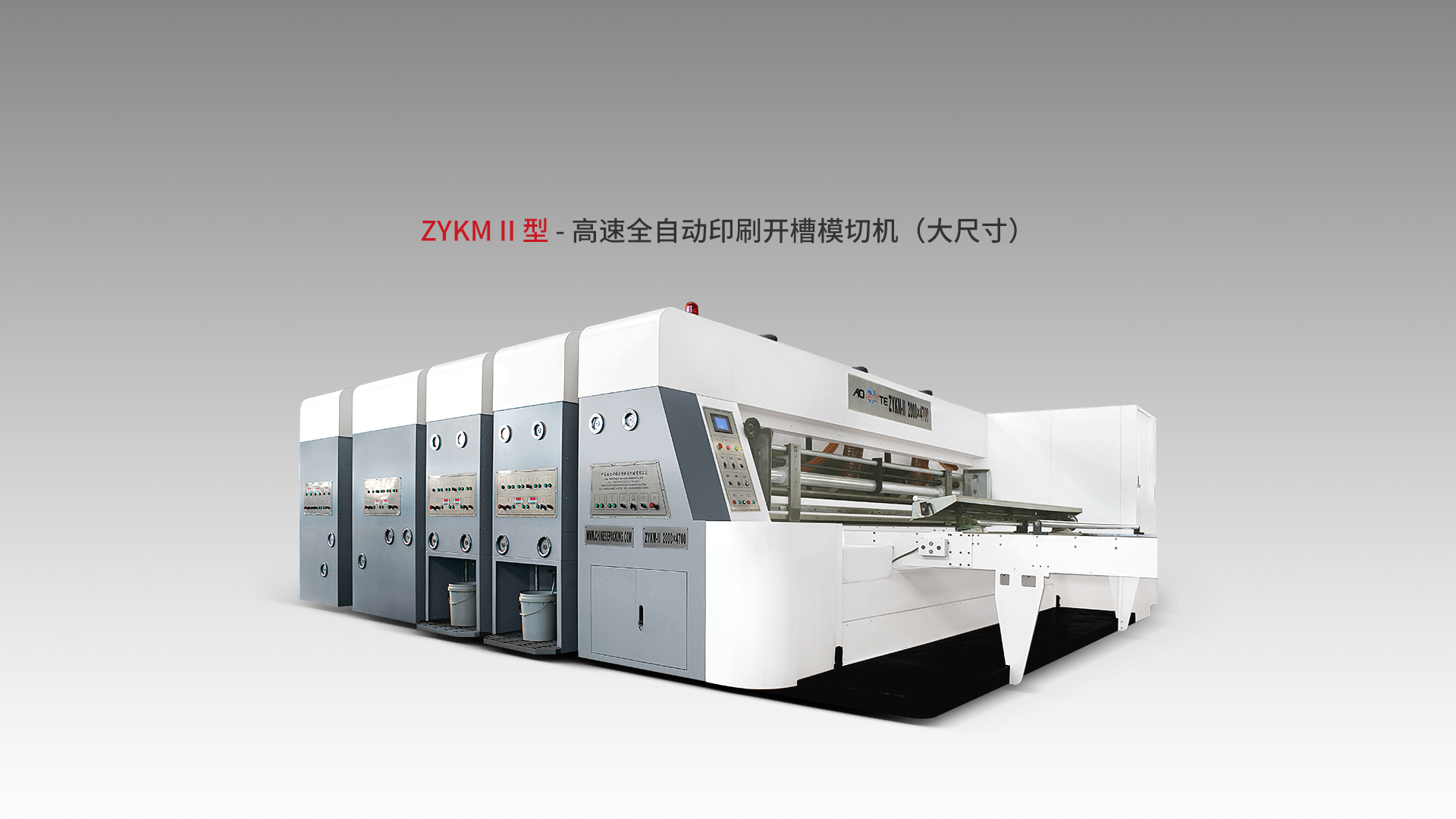

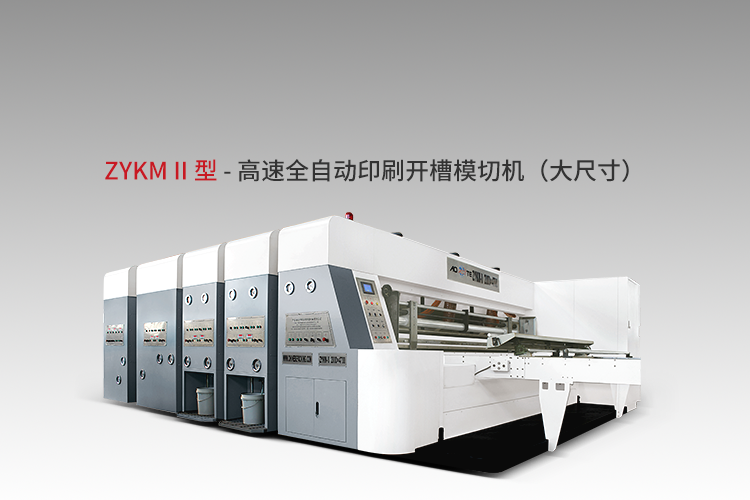

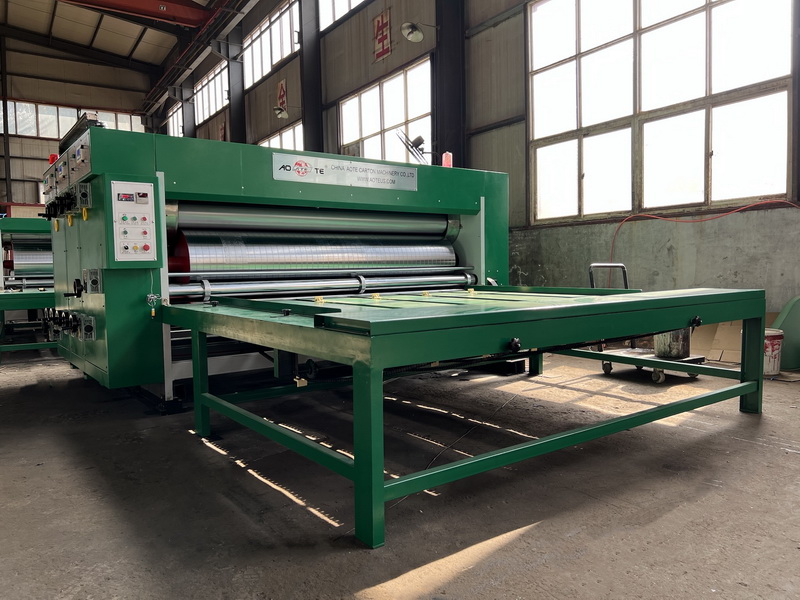

奥特机械-固定式印刷开槽

模切粘箱联动线专业制造商

模切粘箱联动线专业制造商

“AOTE”商标为安徽省著名商标,蚌埠市知名品牌

蚌埠市奥特纸箱机械有限公司是专业生产中高档成套纸箱设备的公司,高新技术企业。海关A类管理企业。公司通过了欧洲CE安全认证和ISO9001:2015国际质量体系认证。产品畅销全国,并出口到美洲、欧洲、非洲、西亚、南亚、东南亚等47个国...

-

36年since1986

36年since1986 -

27000㎡占地27000平方米

27000㎡占地27000平方米 -

47+产品出口47个国家及地区

47+产品出口47个国家及地区

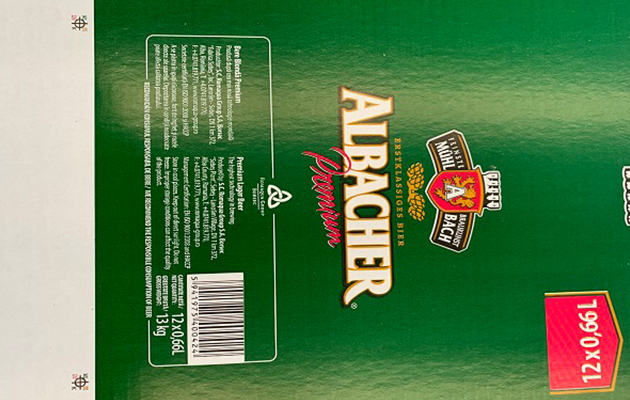

GLOBAL

全球客户